For TEMSA, it is fundamental to guarantee the quality, safety and transparency of all processes, so each stage is carefully documented through performance indicators that guarantee the fulfillment of our work.

The quality team is present at every stage of the process, which allows us to meet 100% of customer requirements in a consistent and reliable manner.

We strive to maintain safety throughout the process through rigorous measures and protocols that protect our personnel and our customers while maintaining a clear and accurate line of communication about our products, services and policies.

- 1

- DESIGN AND DETAILED ENGINEERING

- 2

- INSPECTION AND RECEPTION OF RAW MATERIALS

We ensure that raw materials meet established standards and specified requirements, thus guaranteeing the quality of our products and ensuring that the final products meet established quality standards and satisfy our customers' needs and expectations.

At TEMSA, we are committed to maintaining high quality standards in our products, which begins with the rigorous selection and evaluation of our raw materials. Through a meticulous inspection and receiving process, we ensure that raw materials meet established standards and specific requirements.

Our priority is to ensure that the final products we deliver meet the highest quality standards. To achieve this, we implement strict quality controls at every stage of our supply chain.

- 3

- MECHANICAL CLEANING

At TEMSA, we employ a highly effective cleaning method to remove impurities, residues, oxidation and other contaminants from surfaces. This thorough cleaning is essential to carefully prepare the surface and ensure complete protection of the substrate.

By using this specialized cleaning method, we can achieve optimal substrate protection, which in turn reduces long-term maintenance costs.

Our dedication to quality and meticulous surface care enables us to provide reliable and durable solutions.

- 4

- CUTTING AND DRILLING OF PROFILES

- 5

- CUTTING, BORING, MACHINING AND PUNCHING OF PLATE

- 6

- ASSEMBLY

Our quality department is present in every process to ensure compliance with customer requirements.

- 7

- COATING

Water and solvent based basics through to epoxy systems, polyurethanes, zinc-rich epoxy systems, fire protection systems and galvanization.

- 8

- PRE-ASSEMBLY

Through this process, we guarantee that the parts fit properly and that the final assembly is successful, meeting the established quality and functionality standards.

We verify and guarantee the correct alignment, adjustment and functionality of the parts before their final assembly.

- 9

- TRANSPORTATION

- 10

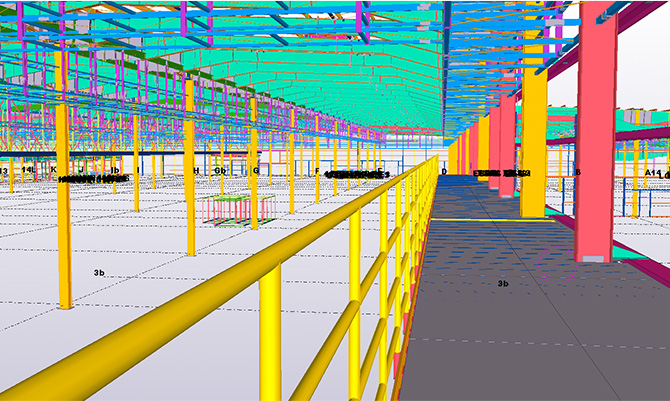

- BIM MODELS

At TEMSA, our main goal is to work towards efficiency. We know that it all comes down to having the right people, the right tools and the right processes. That is why we have embraced the use of BIM (Building Information Modeling), a technology that has gained popularity due to its ability to exchange data, which has resulted in more efficient collaborative work environments.

For TEMSA, the BIM system offers the following uses:

- Visualize the project and ensure that everything necessary for its success is in place.

- Visualize possible conflicts that may arise during the design phase.

- It also acts as a tool to train workers on specific tasks in a safe environment.

- We transport our team of professionals to a world where we can visualize 3D models from different angles and thus guarantee the success of your project.